|

|

0%

Abstract: Frostytech departs from the usual pixel fodder for a brief look at some cooling technologies you have never seen before. We touch on some fun tests from the unpublished Frostytech archives and collect all the thermodynamics research we've reported on into one location.

|

Home >

Reviews >

Page: Annex C) Heat Exchangers, Microchannel, Capilliary, Spray Watercooling

|

Microfluidic Cooling Channels On the CPU

:

RIT: "Dr.

Satish G. Kandlikar, Gleason Professor of Mechanical Engineering at RIT,

received an IBM Faculty Award for the second consecutive year to conduct

research on liquid cooling of next-generation computer chips. To achieve

this, microchannels are etched directly on the back side of the computer

chip and water is circulated to carry the heat away. This fundamental

research is aimed at increasing the cooling rate from around 50 Watts/cm2

to well over 500 W/cm2. The chips are fabricated by IBM at their T. J.

Watson research center. This work has been conducted at the Thermal

Analysis and Microfluidics Laboratory at RIT by Mark Steinke, who

successfully defended his doctoral thesis in microsystems engineering this

past academic year. Future work in this area will focus on utilizing

boiling in these chips. " |

Purdue University Microchannel Cooling

System:

"At Purdue University,

Mudawar and doctoral student Jaeson Lee have already demonstrated the

potential of their microchannel heat sinks. “We really have a working

system now,” said Mudawar, whose study is funded by the U.S. Office of

Naval Research. Mudawar and Lee were able to successfully use a one-inch

square copper microchannel plate to serve the same evaporative cooling

function as the one-meter long tubing used in a refrigerator. “The issue

now is going to be packaging the cooling system around the device."

"Developed by researchers at Purdue University, this copper microchannel heat sink contains numerous

grooves each 231 microns wide — about three times as wide as a human hair

— and 713 microns deep."

" By modifying conventional refrigeration

technology with the tiny devices, they could be used to cool space,

military and computer systems."

|

Soliton R&D Corp Kapton Polymide Ribbon Capillary CPU

Liquid Cooling :

Nikkei Electronics Asia

reports on a Kapton Polymide ribbon capillary CPU liquid cooling system by

Soliton R&D Corp of Japan. ; "A new type of water-cooling technology

has appeared to handle IC heating issues in PCs and other equipment.

Compared to existing water-cooling modules it seems to offer better heat

radiation performance, smaller and lighter specs, and cheaper

manufacturing. The new technology is under development by Soliton R&D

Corp of Japan, a technology start-up involved in R&D of flexible

circuit boards. The basic approach is to form an extremely fine network of

channels through Cu foil, passing the water or other cooling medium.

Eventually the firm hopes to form it as an integral part of the printed

circuit board (PCB) or flexible circuit.

The firm

commented that the prototype is already capable of cooling the surface

temperature of a 150W IC low enough for normal operation. One of the

reasons that Soliton's design achieves such high cooling performance is

that it uses fine pipes - or capillaries. The total surface area can be

maximized in comparison to the coolant volume, boosting performance. For

example, the A4-size Cu sheet used as the radiator has a large number of

capillaries running parallel, with a length of over 3 meters each for a

total path length of 30 meters. The capillaries are 1.5mm in width, and

150µm deep. Both dimensions were based on the performance of the existing

pump, and will be reduced to about 50µm square in future designs. These

numbers are on a par with the "microchannel" design under development by

Intel and others for microprocessor cooling.

A smaller capillary cross-section means that the Cu sheet can be made

thinner, which is the key to smaller and lighter modules. The Cu sheet

used in the prototype was 0.4mm thick, but Soliton expects to be able to

reduce this to 70µm. At 0.4mm, the A4-size Cu sheet weighs over 200g, but

this would be reduced to under 40g if only 70µm thick." |

|

Spray Cooling with Isothermal Systems

Research :

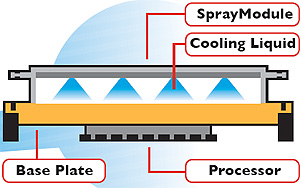

Isothermal Systems Research (ISR) have developed a CPU

cooling technology called Spraycool, which

replaces traditional heatsinks with a rather novel form of liquid cooling

that utilizes jets of atomized fluid sprayed onto a cold plate in a fully

enclosed environment.

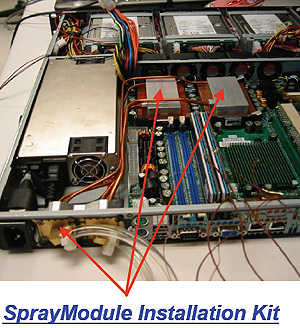

The SprayCool Technology has

being designed for use with High Performance Servers in racked

configurations, in the above example, wherein the liquid cooling system

removes the heat from the rack and centrally cools it, thereby decreasing

overall energy costs. The server rack system by ISR operates with 3M Fluorinert

and consists of a SprayModule, Fluid I/O, and 3U Thermal Management

Unit.

The fundamentals of the technology are outlined in greater detail in

the mfgr's whitepaper, and apparently capable of handling a

heat flux from 100W/cm2 to 2000 w/cm2. Essentially though, the apparatus

operates under the following principles; "A non-conductive and

non-corrosive coolant is atomized and sprayed directly onto electronics to

provide cooling. The coolant vaporizes and heat is rejected to the

enclosure and/or through a heat exchanger, condensing the vapor back into

a liquid state. The process continuously cycles within a closed loop

sealed enclosure that prevents corrosive environmental contamination from

harming sensitive electronics."

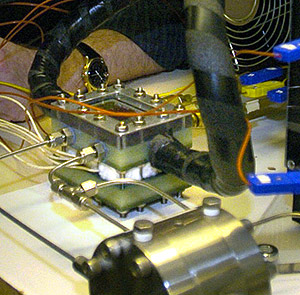

Another research paper from the University of Wisconsin-Madison offers

better insight into the construction and engineering behind a spray cooling

module.

|

|

|

|

1:

Cryo Tech and New Cooling Technologies You Have Never Seen

2:

Thermoacoustic Cooling

3:

Phase Change Waterchilling

4:

Conduction PCB Cooling via Cold Plate Heat Exchangers

5:

The Stirling Cycle Cryo Cooler

6:

Annex. A) Graphite, Carbon Foam/Fiber, Polymer Heatsinks

7:

Annex A) Graphite, Carbon Foam/Fiber, Polymer Heatsinks

8:

Annex B) Diamond, Nano-structure and Metal Foam Heatsinks

9:

Annex B) Diamond, Nano-structure and Metal Foam Heatsinks

10:

Annex C) Heat Exchangers, Microchannel, Capilliary, Spray Watercooling

11: — Annex C) Heat Exchangers, Microchannel, Capilliary, Spray Watercooling

12:

Annex C) Heat Exchangers, Microchannel, Capilliary, Spray Watercooling

13:

Annex D) Computational Fluid Dynamics and Innovative Heatsink Tech

List all FrostyTech heat sinks that Frostytech tested?

|

|

|

|

|

Websites you may also like:

PCSTATS

|

|

|