| NengTyi XPC5000 From All Angles |

|

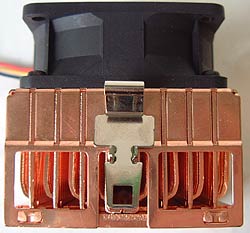

The Fan:

The YSTech fan is 25mm thick and spins at 5000RPM so it is a good source of airflow and little noisy. There isn't much space between the bottom of the fan

the tips of the many copper fins; this can sometime help to improve airflow down through the fins. |

|

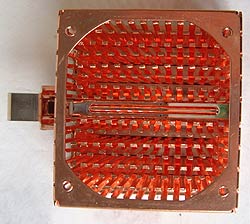

Side

A: The XPC5000 is really nice

to look at with all of this copper. There are eight main fin sections which have been split into alternating 2mm square sections for increased airflow.

The end result is to create a good path for heat to flow from the base to the tips. By punching out the square pins from larger fins NengTyi are able to minimize the number of joints which contact the base of the heatsink. |

|

Side B:

The fan shroud is made from copper as

well and is merely press-fitted to the base. Perhaps added thermal performance could be gained if the shroud were soldered to the base and side fins. In any case, the slices in the shroud help to steady the fin sections and prevent them from becoming bent. Each fin section is made from 1.25mm thick copper. The main sections are spaced 6mm apart. The clip is easy to use an requires no tools! |

|

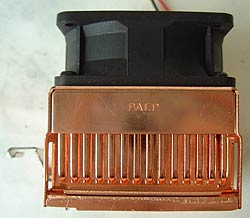

Side B:

The base

measures 5mm thick which is about

the norm

for copper. You can really see from

this side how the manufacturer has taken one piece of metal, punched out the

fins and created many pins. The fin bends in a "U" shape at the base and

is joined to the baseplate by a means not visible. It is

difficult to say if the fins are soldered, glued or dip-brazed to

the base. The shroud comes down 15mm to help direct air

flow. |

|

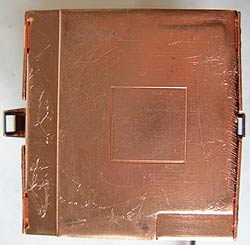

Heatsink Base:

Sadly, the base of the XPC5000 is not that much to look

at. We could do without the stamped

area, and could do with some nice machining to smoothen and flatten

things out. As it stands the base is actually very flat, but

really ought to be lapped for some added surface

treatment.

|