|

|

0%

Abstract: First impressions of heatsinks have a tendency to be swayed by how shiny or strange looking the heatsink is.

|

Home >

Reviews >

Page: Looking at the heatsink from all angles

|

| Titan TTC-D6TBA Heatsink From

All Angles |

|

The Fan:

Rotating at a

listed speed of 5000 RPM with one ball bearing and one sleeve

bearing may be the recipe

for a fairly quiet 60mm fan, or it may just be a coincidence.

In any regard, the heatsink we tested ran smoothly and relatively

quietly. An integrated alarm on the fan wire sets off a loud alarm

when the power is on and the fan impeller motionless.

A good bit of insurance in the event of a malfunction. The fan

connects to the motherboard fan header and supports RPM monitoring. |

|

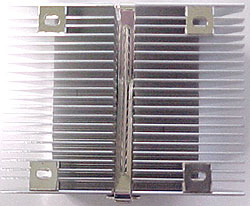

Heatsink Top:

The undercut brings the base

width down from 80mm to 51mm and makes it possible to actually mount this heatsink

on a socket. Were the width to remain the same dimension all the way

down, it is doubtful that the D6TBA would fit

on many motherboards. The fan attaches directly to the heatsink fins by means

of small steel clips. The fan sits flush against the tips of the heatsink fins. The clip sits

in a 7mm trough which cuts into the base leaving only 6mm

of depth where there was originally 9mm. |

|

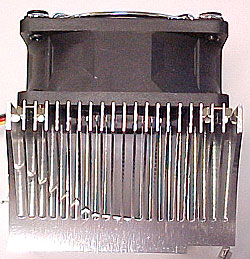

Side A:

The fins on the D6TBA are just under a millimeter

in thickness and taper towards the top. Each fin is spaced widely at 2mm, and measures ~31mm. The base area of the extrusion is 9mm thick

and undercut to allow clearance over the socket cam arm - something which many first generation

heatsinks overlooked. |

|

Side B:

The rounded

overhangs on this heatsink give it a unique look and also help it

to clear large capacitors which are commonly placed too near to processor sockets.

A generic tool-based clip is used to attach the D6TBA in place and is not

overly stiff for that purpose. All of the fins, and the outside

of the heatsink are smooth, and plated in some metal, perhaps

nickel. |

|

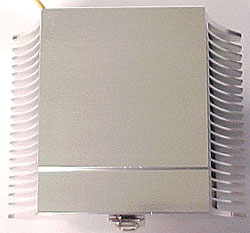

Heatsink Base:

The baseplate measures 51x63mm and

the finish is that of a raw extrusion. The entire heatsink has been

plated in a secondary metal, perhaps nickel, which gives it a nice sheen and seems to smooth out

many of the fine pits. The smoothness of the base finish is quite good,

but in terms of flatness things are a bit concave. This is a common

occurrence for raw extrusion heatsinks and little bit of lapping to even

things up would go over well. Overall, it is better than

many of the raw aluminum bases we have seen in the past

as there is a complete absence of deep scratching - another common occurrence.

|

|

|

Websites you may also like:

PCSTATS

|

|

|