360° View - Coolage Freezer

Orb Heatsink

Information on Frostytech's test

methodology is available

here. | |

|

|

The Heatsink Fan:

The Coolage Freezer Orb heatsink uses a

95x95x25mm PWM fan that spins at 1000-2800RPM. There is no wire fan grill to

protect the impeller from errant wires inside the computer case. The fan draws

power from a standard 4-pin PWM motherboard fan header, and is backwards compatible with

3-pin connectors. |

|

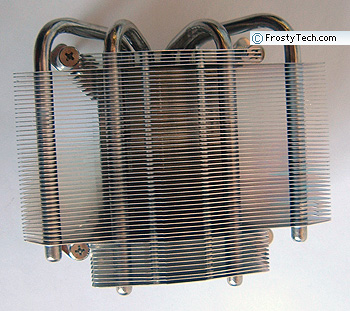

Heatsink

Exposed:

With the fan removed the different parts of the Coolage

Freezer Orb heatsink are clearly visible. It's four 6mm diameter heatpipes overlap

the base of the cooler completely so as much heat as possible is absorbed

at the source. The heatpipes fan out to transfer the heat to

different areas of the 0.3mm thin aluminum fins. Each fin is spaced 1.3mm

from the next. The copper heatpipes are soldered directly to the copper base

plate, and the aluminum fins are swaged over the heat pipes. |

|

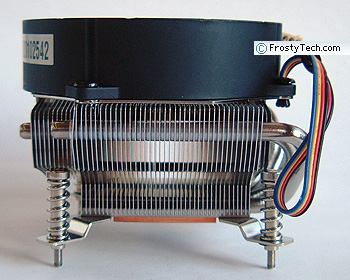

Heatsink Side

A:

The body of the Coolage Freezer Orb heatsink stands

42mm tall, and the heatsink has an overall height of 71mm. The copper base is ~3.5mm thick.

The four heatpipes are soldered to the heatpipes for optimal thermal transmission. |

|

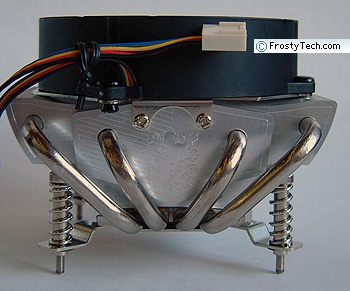

Heatsink Side B:

The Coolage Freezer Orb has some decorative

stamps on the two outer aluminum fins. Note the spring tensioned mounting

screws. Each leg has a collar so the heatsink cannot be installed too

tightly over the CPU. Spring tensioned systems are great because they

ensure even load forces on the CPU. Between the aluminum fins and

heatpipes is a nickel plated aluminum pad that conducts some heat up from

the CPU directly. |

|

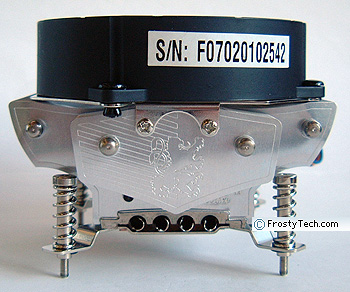

Heatsink Side C:

From the side we can see

that the Coolage Freezer Orb heatsink is built up from about 50 aluminum fins of 109x40mm in size. The four heatpipes reach out

from the base where they are closely located, and spread out through the body of the cooling fins to evenly

distribute the heat. |

|

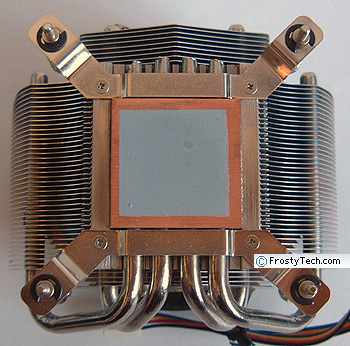

Heatsink Base:

The copper base of the Coolage Freezer Orb heatsink measures 37 x 37mm in size. The copper plate is slightly convex in both axis, likely due to the sanding that was used to finish the surface. Surface

roughness is on the order of ~63 microinches, which is considered satisfactory.

The four 6mm diameter copper heatpipes are soldered to the lower copper

base, and an upper nickel plated aluminum pad that fits in between

the heatpipes and aluminum fins. |