360° View - Coolermaster

Hyper48 Heatsink

Information on Frostytech's test

methodology is available

here. | |

|

|

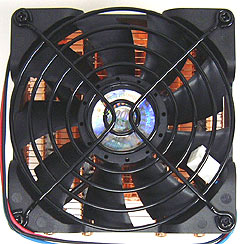

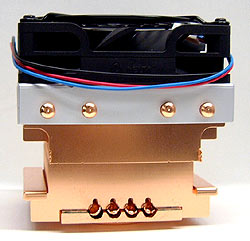

The Heatsink Fan:

A stylish black wire grill shields the 9-bladed impeller on the 92x92x25mm Delta NFB0912L fan.

The upper half of the fan frame is cut away and the edges of

the fan blades are extended a little into that space. This alteration diminishes

the most common source of fan noise - air

entering the fan body. Power comes via a standard 3-pin motherboard fan

header which supports RPM monitoring. According to Coolermaster, fan speed

is 1400RPM. According to Delta that figure is supposed to be 2100RPM.

|

|

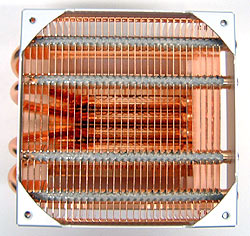

Heatsink Top:

An aluminum fan shroud wraps around the

upper portion of the Hyper48's copper fins and supports the 92mm fan with a 5mm plenum below. The four

heatpipes are spaced a good 26mm and 10mm apart so as not to restrict airflow

entering the body of the cooler by much. The copper fins are 0.3mm thick

and positioned every 2.4mm. Note how the heat pipes converge at the base of

the Hyper48 so they're directly over the CPU core. |

|

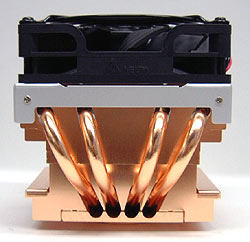

Heatsink Side A:

The four 6mm

diameter copper heat pipes converge at the base of the heatsink directly over the CPU core, which is where

temperatures are highest. The copper base plate is 5mm thick on average, but extends

to 10mm thick where contact is made with the CPU's integrated heat spreader.

|

|

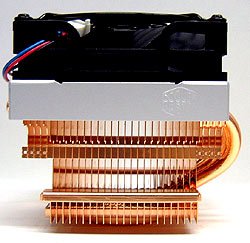

Heatsink Side B:

The Hyper48 is 68mm wide at

the base and 93mm at the top. The copper fins

use interlocking tabs which keep fin-to-fin spacing exact. |

|

Heatsink Side C:

The two shoulders on either side of the

Hyper48 heatsink are for the K8 / P4 heatsink mounting clips to rest on.

When clipped into place over a CPU, the clamping forces are applied to

these two pads. If you look at the side of the Delta fan you can easily see

how half the frame is split open. The heatsink stands 96mm in height. The

fan is 25mm thick. |

|

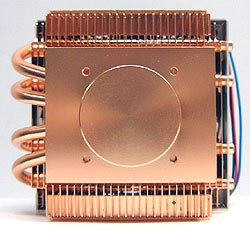

Heatsink Base:

The copper base measures

68x55mm and is responsible for distributing heat from

the CPU to the heatpipes and copper fins. The four screw

holes surrounding the round 40mm portion are for the LGA775

mounting clip to attach to. An engineer's straight edge shows us

that base flatness is excellent, with surface roughness being about 8

microinches or thereabouts. |