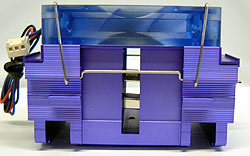

360° View - Evercool

Magic Cooler MAG01-CA Heatsink

Information on

Frostytech's test methodology is available

here. | |

|

|

The

Heatsink Fan:

The 15x70x70mm fan spins at 3500RPM and moves

about 27CFM according to official data. There is no fan guard, or

illuminating LEDs for the translucent blue impeller for that matter.

The fan draws power from a standard 3-pin motherboard fan header that

supports RPM monitoring. |

|

Heatsink Top:

An extruded aluminum fan

shroud supports the 70mm fan just above the tips of

the fins, creating a 4mm plenum. It also provides a platform for

the socket 478 mounting hardware. A large 7mm wide cross-cut goes down the

center of the heatsink. This space is for the K7 mounting clip. The K8 clip

fits in between the fins, with a small tab in the cut to

prevent lateral movement. |

|

Heatsink Side A:

The K8 mounting clip is very stiff, and screws directly into the back plate. The Evercool MAG01-CA heatsink

fins average 30mm high, 1mm thick, and 38mm wide. Fin spacing

is kept at a very typical 2mm. The extrusion pattern includes a recess for

the socket cam arm of sockets A and 370 processors. The aluminum base

is 8.5mm thick, but doesn't extend the full length of the heatsink.

|

|

Heatsink Side B:

Wire clips hold the fan in place, screw holes

are set into the shroud so larger fans can easily be added

if the user has appropriately sized screws at hand. Two very deep 10mm

wide cuts are made into the base of the heatsink either side

of the copper insert. These cuts are 12mm deep, and completely cut

through the extrusion's base. We can only assume the idea is to get airflow moving down and into

the area around the CPU socket. Such a design choice certainly affects the

ability of the heatsink to conduct heat towards its outer edges. |

|

Heatsink Base:

The 10mm wide cuts in the base reveal the underside of

the extrusion's fins which are

certainly going to loose some effectiveness in the heat transfer department. The copper

insert is 35mm in diameter and has a surface finish of approximately 16 microinches which is very good. The surface flatness of the copper is good, but the surrounding aluminum is not exactly flush with

it. |