| Zalman CNPS7000A-Cu

Heatsink From All Angles |

|

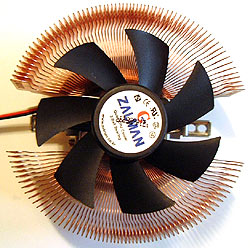

The Fan:

The fan Zalman

use with the CNPS7000A-Cu is 84mm in diameter, and about 25mm tall. Rotating at 2400RPM, the

fan moves air without creating a lot of noise. The fan connects via a

standard three pin motherboard header which supports RPM

monitoring. Zalman's Fanmate 1 can be used to further decrease the speed of motor for even quieter operation

if desired. Decreasing the speed of the fan will impact on the heatsinks performance by a

certain degree since less air is moving over the copper fins. |

|

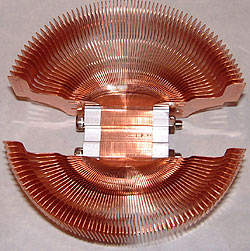

Heatsink Top:

With the fan and spring clip mechanism

removed we can see the CNPS7000A-Cu for all it is worth. The entire

heatsink is made from an assembly of individually punched out sheets of

0.4mm thick copper, the assembly is then squeezed together under high

pressure and bolted tight. The central base section is ~26mm wide, and

from tip to tip the heatsink measures approx. 110mm x 110mm. It looks

circular, but is more oval shaped really. The cut out in the center of the

base section is for the clipping mechanism which applies pressure at the center of

the heatsink. |

|

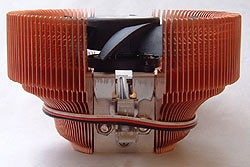

Side A:

From this side we can see just how

the

copper fins gradually

come together to form the body of the heatsink

itself. Compressed under high pressure the fins come into perfect contact at the base which

is then machined absolutely flat and smooth. The bevel in the shape of the

heatsink is so it will clear the HSRM, and any capacitors placed near to the

socket. |

|

Side B:

Standing 62mm high, the CNPS7000A-Cu is fairly compact

all things considered. Most heatsinks have the fan mounted on top of

the fins which

can raise the overall height of a cooler to well over

80mm. The copper fins are spaced about 1mm apart at the outside edges. The spring clipping

system is mounted to the heatsink in such a way that there is no chance of

play. |

|

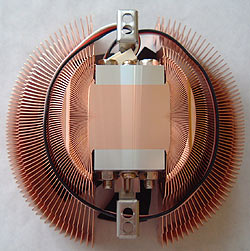

Heatsink Base:

If you ever wanted to see the example

of a perfect heatsink base finish look no further than the

Zalman CNPS7000A-Cu... Milled perfectly flat, there are no machining marks visible - the

surface is very flat and smooth, but not polished. The little aluminum blocks are

used during the compression process to help apply even pressure, and for

the mounting hardware to attach

to. With a base finish

of this calibre, only a very small amount of good quality thermal compound is necessary. Also

note the two sets of holes in each side of the mounting clip, the inside

holes are for a P4 mounting system, and the outside for

Athlon64/AthlonXP. |