|

|

83%

Abstract: At 300RPM the SP411C5 is good in the noise department, but at higher temperatures it can get somewhat loud.

|

Home >

Reviews >

Page: Closer Examination of the Heatsink

|

| Spire SP411C5

Heatsink From All Angles |

|

The Fan:

The 70mm fan measures

25mm thick and sports an seven

bladed impeller. The fan

produces minimal

noise, though it draws 0.4A under power. With a metal wire grill attached to the

fan, problems with loose wires getting caught in the blades should be avoided. The fan connects

to the motherboard fan header through a nylon meshed wire, and supports RPM monitoring. |

|

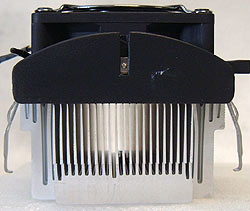

Heatsink Top:

There are a series of seven 2mm wide

crosscuts on either side of the heatsink which have probably been made

to improve exhaust airflow at the outer edges. The

cross cuts also provide a space for the thermal sensor from the

fan to be tucked away. The fins are all smooth faced, and separated 1.5mm apart. Each

fin is slightly tapered from the bottom to the top. The lever around the fan

swings to one side to lock in a set of spring clips into

the HSRM. |

|

Side A:

The aluminum base measures ~11mm thick, and contains a nice copper core. The fins are 30mm tall, and are just 1mm thick. The top portion

of the heatsink has a rather larger plastic fan shroud and retention mechanism built into

one apparatus. By moving the lever 180 degrees the stainless steel spring clips close

in, locking the heatsink pretty securely into the HSRM. The Spire SP411C5 heatsink stands 76mm tall. |

|

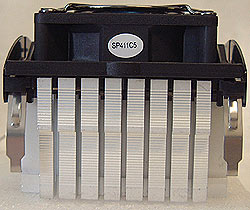

Side B:

Here we see another shot

of the clip mechanism which is used to lock onto the HSRM. Each

corner has a small metal tab which locks into the plastic tab to hold the Spire

SP411C5 firmly in place. The outside of the heatsink has a serrated finish, mainly to improve

grip. |

|

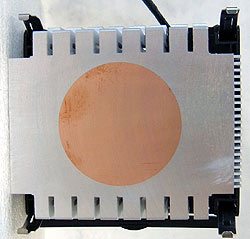

Heatsink Base:

The cross cuts slice 8mm into the sides of the

SP411C5, and after a quick check with the machinists' straight edge we can

clearly see that the base has been very well finished. The surface is perfectly flat, and very smooth (a quick test is simply to check if the crystalline structure of the

aluminum is visible via some reflected light - and it is). The copper insert is 45mm

in diameter, and probably 6-8mm thick. A hole is drilled into the base and the

copper plug squeezed in under higher pressure for a good interference

fit. |

|

|

Websites you may also like:

PCSTATS

|

|

|