TOP 5 Heat Sinks TOP 5 Low Profile Heat Sinks TOP 5 Liquid Coolers

Heatsinks by Brand / Mfgr Reviews + Articless Advanced Search

|

TOP 5 Heat Sinks TOP 5 Low Profile Heat Sinks TOP 5 Liquid Coolers Heatsinks by Brand / Mfgr Reviews + Articless Advanced Search |

UPDATE:

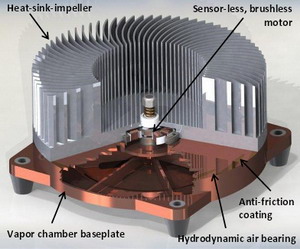

Recently, a few curious Frostytech readers have asked; "what's happening with the Sandia Air Bearing Cooler?" That's a good question. We made some inquires and have a bit of new information to share. In case you missed Frostytech's original story, the Sandia Cooler is a novel heatsink under development by researcher Jeff Koplow at Sandia National Labs in Livermore, California. What makes this prototype heatsink special is the design, its aluminum cooling fins serve double duty as the rotating fan and fan blades of the cooler . Unlike traditional CPU coolers, heat energy in the Sandia Cooler is conducted across a very thin air gap bearing from the stationary base of the cooler to the upper rotating aluminum fin/fan component. This aspect of the novel cooler design tends to challenge people's expectations as it seems impossible for a heatsink to work this way. August 2013 Updates What's new? For starters, as of late August 2013 development of the v5 Sandia Cooler continues. The research team are currently testing modifications to the controller board and working to mature several aspects of the technology in preparation for the next phase. Secondly, the researchers have asked to address some misconceptions about the underlying capabilities and technology in the Sandia Cooler. Please note that Frostytech hasn't tested the heatsink, nor even handled a unit yet. It works independent of orientation

Several of the more frequent misconceptions about the Sandia Cooler are addressed below by Jeff Koplow, lead researcher for the project.

Previously... Introducing the Sandia Cooler The point of this three piece, prototype spinning aluminum impeller heatsink is to get rid of boundary layers by exploiting a fairly obscure fluid dynamic effect first discussed in the 1950's; boundary layers are substantially thinned above the surface of accelerating bodies (ie. radial fins on a disk rapidly spinning). In this case, the aluminum cooling fins - the fan impeller - are spinning at 2000RPM. According to Sandia Labs, heat is transferred from the processor to the rotating cooling component across a very thin 'air bearing' - essentially a metal surface rotating a fraction of a millimeter over a similarly sized stationary surface.

Watch the entire YouTube video on the Sandia air bearing cooler, it's well shot and explained in laymen's terms.

The complete 48 pg PDF from Sandia National Laboratories researcher Jeff Koplow, titled; "A Fundamentally New Approach to Air-Cooled Heat Exchangers" is available here. The project report 'borrows' one of my photos from a Frostytech review without crediting it to Frostytech.com (pg.5, figure 1), but this technology is cool so I'll let it slide. ;) Update - received a nice apology regarding the unattributed image and all is good. :)

|

|

|||||||||||||||||||||||||

|

Find a Heatsink . Latest Heatsink Reviews . Top 5 Heatsinks Tested . Top 5 Low Profile Heatsinks . Top 5 Liquid Coolers . Heatsinks by Mfgr / Brand |

Social Media |

FrostyTech.com Info . Feedback . Contact Us / Heatsink Submissions . Submit News . Privacy Policy |

| |

© Copyright 1999-2025 www.frostytech.com All Rights Reserved. Privacy policy and Terms of Use Images © FrostyTech.com and may not be reproduced without express written permission. Current students and faculty of accredited Universities may use Frostytech images in research papers and thesis, provided each image is attributed. | ||||