360° View - Zalman CNPS8000 Heatsink

Information on Frostytech's test

methodology is available here. | |

|

|

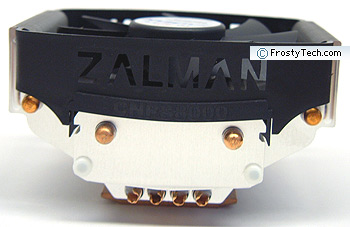

The Heatsink Fan:

The 92x92x25mm fan spins

at 1400-2600RPM with the Fanmate 2 attached, producing as low

as 36 dBA according to our measurements. The lack of any fan guard

presents a challenge for systems with many loose wires dangling around inside

the case, but this also allows the CNPS8000 to operate more

quietly. The fan draws power from a standard 3-pin motherboard fan header

that supports RPM monitoring. Behind the fan blades you can see how the heatsink

has its heatpipes dispersed widely, two at the center and two at either corner. |

|

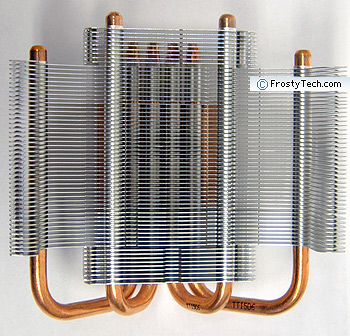

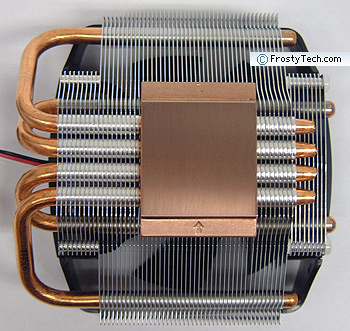

Heatsink Top:

With

the plastic fan shroud and fan removed from the center of the CNPS8000 heatsink,

the layout of this Zalman heatsink becomes very clear. The four 6mm

diameter heatpipes overlap the base of the cooler completely so as much heat

as possible is absorbed at the source.

The heatpipes fan out to transfer the heat to different sections of the 0.3mm

thin aluminum fins, most generally the sections which receive the most airflow from the fan

itself. Each fin is spaced 1.2mm from the next, for what is a very wide

fin pitch. The copper heatpipes are soldered directly to the forged copper base.

Where the fan motor sits, the aluminum fins have been recessed slightly

to accommodate. |

|

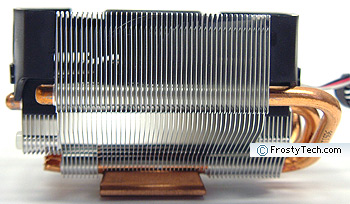

Heatsink Side A:

From the side we can see the 63mm tall Zalman

CNPS8000 heatsink is composed of aluminum fins measuring

25x60mm and 108x40mm on average. The plastic fan shroud is just begging for

a LED illuminated fan with that "Zalman" logo cut into it, so we can

only assume the company is set to release such a model in the near future. There is about

27mm clearance at either side of the CNPS8000 for adjacent components. Where the 90-degree jut is, the

clearance is 35mm. |

|

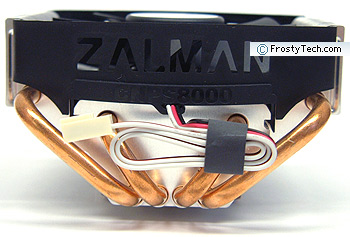

Heatsink Side B:

The four 6mm copper heatpipes run from the heatsink base plate out towards the sides of the CNPS8000 heatsink, rather than to just evenly spaced

increments. Many manufacturers make this mistake, and don't take into account

the different fan air pressures when laying out where heatpipes will go. |

|

Heatsink Side C:

The copper base is ~7mm thick, and soldered to each of the four

copper heatpipes. In the way that the aluminum fins are assembled, it is

actually the copper heatpipes that hold the entire CNPS8000 heatsink

together. This concentrates the path heat can take to four very specific

lanes. The wide fin spacing almost ensures a relatively transparent

heatsink, and little airflow resistance. |

|

Heatsink Base:

The forged copper base measures 37.5mm

x 36.5mm where it makes contact with the processor. The copper base has

been machined flat, and very smooth. Surface roughness is on the order of

~16 microinches, which is considered excellent. Again, from this angle the

layout and cleverness of construction of the Zalman CNPS8000 heatsink are

readily apparent. The only question that remains is whether aluminum fins

or copper fins will provide the best thermal performance in the long run. I

also have to wonder if connecting the aluminum fins to the

heatpipes at the base is the best possible solution... it seems

that transferring heat towards the tops of the cooling fins would have

been preferred, if less uniform. |