|

|

78%

Abstract: The fan adaptor of course reduces noise by allowing Aopen to use a larger fan, and hence a slower rotating impeller.

|

Home >

Reviews >

Page: Close examination of the heatsink

|

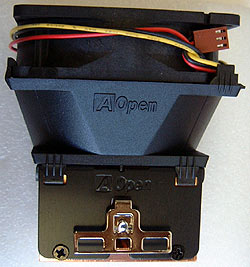

| Aopen ACK7L

Heatsink From All Angles |

|

The Fan:

Nidec have been a

favourite, if often under used fan of us. The fans are built with glass

fiber reinforcing in the plastic to ensure the best possible structural

integrity. The ACK7L fan didn't

come with a fan grill, but considering just how large this

fan is I would suggest adding one of your own. The fan connects to a standard 3-pin motherboard fan header. |

|

Heatsink Top:

This level of fin density

is something you are not going to see very often. Each copper fin is

0.4mm thick, and spaced about 1.0mm apart. Each of the 43 sets of fins measures about 25mm wide and 25mm tall.

The clip sits in a trough 6mm wide. The fan mounts to the shroud leaving approx.

3-4mm clearance from the tips of the copper

fins. |

|

Side A:

The entire heatsink stands 94mm high, with

the heatsink itself taking up just 37mm of that height. The clip used on the Aopen ACK7L is

only operable with a flat headed screwdriver, but it is not difficult to engage

or remove from the socket. There is no protection from the heatsink sliding

on the die in the event the computer is moved, so as with most

heavy copper heatsinks, it is always a good idea to remove it

first,

then transport the computer. Since the clip uses all three tabs on the socket to

keep itself in position it is less likely that the clip will

snap off the socket tabs. It would have been best if the

fulcrum point were keyed so that the clip would not slide within the

heatsink. |

|

Side B:

From a side view the number and density of the

one-piece copper skived fins becomes apparent. Each of those 43 fins is

only 0.4mm thick, and have been

formed from material skived off the base copper

plate. The fins and base plate are the

same piece of copper though, and so there are no joints. The base of the ACK7L is

rather thick, measuring it at a full 10mm. Most socket A heatsink base plates are rarely over 6mm in

thickness. |

|

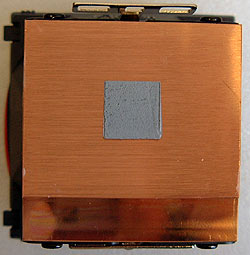

Heatsink

Base:

The base has been machined flat for the skiving

process, and then once that was complete, sanded to achieve a smooth, but

textured surface finish. A small patch of gray thermal

compound comes pre-applied to the base of the ACK7L, which after testing with the straight edge is fairly even

and flat at the center. From side to side there is a bit of

a difference in heights, but this is not too uncommon, and as long as

the central region is flat, that is all that matters.

|

|

|

Websites you may also like:

PCSTATS

|

|

|