| Verax

P16Cu Heatsink From All Angles |

|

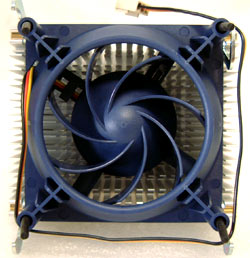

The Fan:

The blue seven bladed impeller on this 25mm

thick KP2-fan creates a small amount of airflow and practically zero

noise. Compared to a traditional heatsink, the CAIRdB is pretty revolutionary

- but it is important to keep in mind that this heatsink is

really meant for zero noise systems. The fan uses two NIRO ball

bearings and is temperature controlled to run at 1400-3500RPM (20C-40C)

depending on temperature. The fan connects to the motherboard via a 3-pin

fan header which supports RPM monitoring. |

|

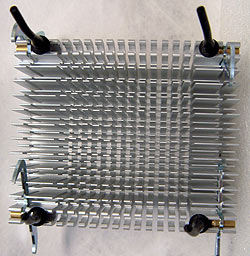

Heatsink Top:

The heatsink is based on a very wide spacing of

pins and uses four rubber anti-vibration posts mounts to hold the fan in place. The fan doesn't actually come

in contact with the metal of the heatsink, and this way any vibrations which

do occur are absorbed by the rubber. The four metal clips rotate freely in a

space with brass bushings and are used to lock the heatsink into the

m478 HSRM. |

|

Side A:

The fins on the extrusion are all

rather thick compared to the standard these days. However, with the relatively low amount of air flow that comes from the fan

the spacing is probably well suited. The little

rubber feet which hold the fan in place lock into small circular holes in the

frame of the heatsink. The copper base plate measures 3mm thick and the fins

range from 1.50mm - 0.8mm at the tips. Fins are spaced ~2mm apart at the

base. |

|

Side B:

The side of the heatsink has an assortment of 2mm

cross cuts which help to increase surface area and induce turbulence

within the fin structure of

the heatsink. The clips are interesting because they rotate around and

use little barbs to lock into the plastic HSRM tabs. The mechanism could use some springs

to tension the clips in the right direction, and make mounting the heatsink a little

easier. |

|

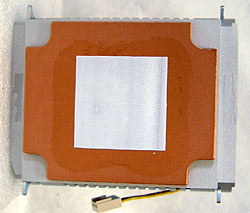

Heatsink Base:

The 65x79mm copper base has a light matt

finish and is very slightly domed at the center. A small amount of

lapping could further improve the performance of the entire heatsink. The

copper is applied to the base of the aluminum heatsink through a technology called Cold Gas Dynamic Spraying.

CGDS has proven very effective at bonding dissimilar metals such as

aluminum and copper. A square of white silicon thermal compound comes

pre-applied to the base of the copper. |