|

Verax P16 From All

Angles |

|

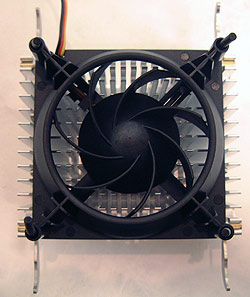

The Fan:

The seven bladed

impeller on this 25mm thick fan creates a small amount of airflow and practically zero noise.

Compared to a traditional heatsink, the CAIRdB is pretty revolutionary -

but it is important to keep in mind that overclocking would

not be a good idea, but use in a zero noise system should

be just fine. The fan uses two NIRO ball bearings

and is temperature controlled to run at 1600-3100RPM (20C-43C) depending on temperature. It connects to the

motherboard via a 3-pin fan header which supports RPM monitoring - but some

motherboards may report inaccurate readings. Motherboard Monitor 5

is supposed to be able to detect the correct value however.

|

|

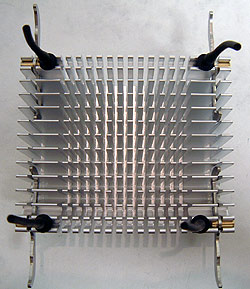

Top: The heatsink is based on a very wide

spacing of pins and uses four rubber anti vibration mounts to hold the fan

in place. The fan doesn't actually come in contact with the metal

of the heatsink, and this way, any vibrations which do occur are absorbed

by the rubber and not passed on to the rest of the

computer. The four metal clips rotate freely in a space with brass

bushings. |

|

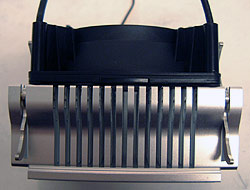

Side A: The fins on the extrusion

are all rather thick to what is the standard these days. However with

the relatively low amount of air flow that comes from the fan the spacing

is probably well suited. The little rubber feet which hold the fan in

place lock into small circular holes in the frame of the heatsink. The base

measures about 10mm thick and the fins range from 3.75mm - 1.5mm at the

tips. Fins are spaced ~3mm apart at the base. |

|

Side B:

The side of

the heatsink has an assortment of cross cuts which help to increase

surface area and induce turbulence within the fin structure of the heatsink. The

clips are interesting, but they don't make me particularly comfortable for situations where the

case may get moved around frequently. |

|

Heatsink Base:

The base is machined flat, and fairly smooth -

there were some slight machining ridges left on the sample we tested. With a Highflow 225-U thermal interface pad

already applied, extra thermal compound is not necessary. However, to keep our results

consistent, we removed the pad and tested with our standard ceramic-based thermal compound

from Coolingflow.com |