|

SF017011 From All

Angles |

|

The Fan:

A Delta fan drawing 0.36A is mounted on top

of the SF017011 heatsink. The fan connects to the motherboard via a standard

three-pin

motherboard fan header. There are about 4mm of clearance below the fan, and above the

square tips of the fins. |

|

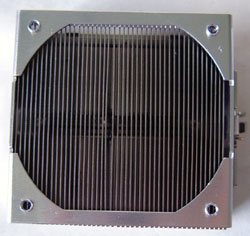

Top: As all the fins are relatively closely

spaced, the square fin tips may cause some problems

with back pressure. It would be interesting to see the results of this same heatsink if those

fin tips were rounded over or pointed to reduce air resistance. The aluminum fan shroud keeps the fan a

few mm above the tips so airflow is a bit better (than if it were in direct

contact).

|

|

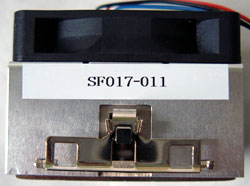

Side

A: The three tab clip is

becoming a must for

socket A heatsinks. With the small unprotected core of AMD processors it is very easy to damage the processor during the removal or placement of the heatsink. Additionally, the high pressures AMD specs call for can sometimes cause the socket clips to shear off, potentially making the motherboard useless. Three tab clips like the one used on the Ajigo heatsink here greatly distribute the forces involved.

|

|

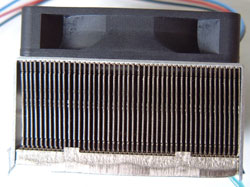

Side B:

The aluminum fins are all nickel plated and measure

0.3mm thick. The fins are spaced 1mm apart and measure about 24mm in height. According

to the manufacturer, the fins are soldered to the base, not dip brazed. The punched out

copper base plate is also nickel plated and measures just over 5mm thick. |

|

Heatsink Base:

The base is simply press cut from a larger sheet

of copper and left unfinished. A large square of T11 interface material

allows this heatsink to be attached directly to the processor with no other work. The material will start to flow once it reaches a certain

temperature and fill in any voids as it does so providing a

pretty good thermal interface. To keep our results consistent, we removed this

material however. The base is pretty flat, but not perfectly so. The

surface finish is very smooth, but some small imperfections from the stamping

process are visible. The relief for the socket cam arm has been

milled out. |