|

|

0%

Abstract: Dynatron have shown us in the past

that they can innovate, and make rather cool heatsinks.

|

Home >

Reviews >

Page: A view from all sides

|

| Dynatron DC1207BMW Heatsink From

All Angles |

|

The Fans:

The 70mm fan is rated at 0.2A and

is fairly quiet in operation. The fan attaches through the aluminum fan shroud directly into

the fins. For the size of the heatsink, I would be

tempted to

add something a little bit bigger, and maybe sacrifice some of the noise for better

cooling performance. The Dynatron fan connects via a 3-pin fan header

on the motherboard. On either side of the fan are the

guides where the Stainless Steel clips go. The small tab prevents the

clips from sliding off the side. |

|

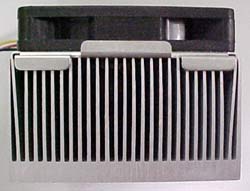

Bare Heatsink:

With the fan removed you can see two things

more clearly. First off, the two clip guides are in direct contact with

the tips of the fins and provide a good means of clipping down the heatsink without large bulky plastic mechanisms. Secondly, we can see

that the fans is held up from the tips of the fins

for better airflow by a few millimeters. |

|

Side A:

The side

of the DC1207BMW is very plane, with no extra cuts to allow warm air to escape, all exhaust is forced

out the left and right sides. The heatsink body itself is 37mm in height, and 83mm

in length. |

|

Side B:

Each of the 27 extruded fins tapers from 1mm thick at the

base to about 0.5mm thick at the very top. The fins are

each spaced 1.5mm apart and the base plate is a standard 6mm

thick. |

|

Heatsink Base:

We've always been fairly picky about the quality of a

heatsinks base, though over time we have to see that almost no manufacturers

machine extruded heatsinks. It is simply much cheaper for them to sand the

base "flat", even though this process tends to leave rather deep

scratches. Still, given the option between this and a raw extrusion base,

the sanded ones are generally better. Raw extrusions, while smooth, are rarely flat.

|

|

|

Websites you may also like:

PCSTATS

|

|

|