|

IHC-H71 From All

Angles |

|

The Fan:YS-Tech make very well known fans amongst performance

users because they, like Delta, produce some high-RPM versions. This

particular fan is noisy, but not so much so as some Athlon based heatsinks will be. The seven fan

blades are protected behind a nice wire fan grill (I don't think to

highly of the laser cut ones) and draws power from a molex pass thru. A

separate three pin connector hooks up to the motherboard from RPM monitoring.

|

|

Top: The two plastic retention clips work well at

holding down the heatsink, but are a little difficult to engage because it

seems as though the plastic is going to snap - the pressures are pretty

taught. The fan attaches to the aluminum fin with screws and the heatpipes are

positioned just under where the air moves fastest. The heatpipes transverse the entire width of the

copper heatsink and supposedly help the cooling process. By how much we aren't really too

sure. |

|

|

Side A:

On one side of the heatsink the heatpipes come out from the center and

then wrap around and to the outside so they form a path for heat

to follow. The idea is to take heat from directly over the processor and move it

to the tips of the copper fins for faster dispersal. The heatpipes are hermetically

sealed and 4mm in diameter. |

|

Side B:

The

vertical copper fins are 0.5mm thick and spaced

1.7mm apart. The fins are presumably dip-brazed to the base. Dip brazing is a

fast and effective way to make a secure metal-to-metal bond between the fins and base

with little metal distortion. The base of each fin has a small tab which helps make this joint

nice and strong. The heatpipe intersects the fins about 17mm up from the base. |

|

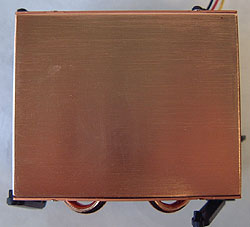

Heatsink Base:

I always recommend everyone look at the base of

heatsink before making a final decision to purchase. The Coolermaster here has a sanded

base which is pretty flat directly over the processor mounting area. The base need not be lapped,

but some good thermal compound should be

used. |