| TI-V77N Heatsink From All

Angles |

|

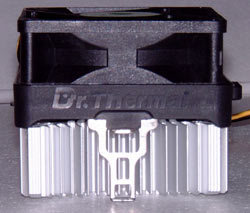

The Fan:

The unlabeled fan is reported to

spin at 5000RPM and considering the amount of noise it generates this

would seem to be a fair

number. The fan is 60mm in size and 25mm thick. Apart from the odd

arrangement of fan blades and orientation of the entire unit

it is otherwise very standard. The fan connects to the power

source via a molex pass thru cable, and uses a small three-pin connector

to deliver the RPM signal to the fan header. |

|

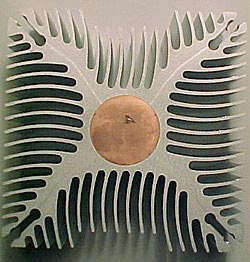

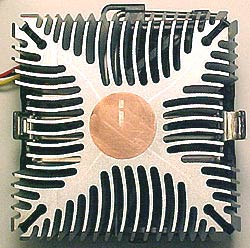

Heatsink Top:

The heatsink top is just

about the same as the heatsink bottom, but bear with us for a moment. Each

side of the TI-V77N has 15 curved fins that range in length from 4mm to

23mm. We were impressed to see that the fins were scalloped on both side

to increase surface area and promote turbulence. Also note that screw

holes have been made in the extrusion to accept both 70mm and 60mm

configurations. The central copper core appears to be 20mm in

diameter. |

|

Side A:

No matter how much we would all

like to see tooless heatsinks become standard, the TI-V77N does require a

small screw driver at some point. Much of the tensioning is taken up by

the small lever on the left hand side. Each of the 15 fins are roughly

0.9mm thick and 21mm tall. The fins are spaced widely at 3mm distances.

|

|

Side B:

The fan shroud which

supports the unlabeled fan 6.5mm above the top of the heatsink also doubles as a

frame for the attachment mechanism and lever. The base of the heatsink has

a bevel to help keep fingers from being sliced up. The base is undercut

2mm to clear the socket cam arm. |

|

Heatsink Base:

Looking at the base

of the TI-V77N is like looking at the top of it. Unlike traditional

extruded heatsinks this one is essentially sitting on its side. The base finish

is very good, and the left hand side undercut 2mm for socket cam

arm clearance. The heatsink comes with a small patch of gray wax-like

phase change material over the copper core. We removed this material

before conducting our thermal tests |