|

|

0%

Abstract: Frostytech departs from the usual pixel fodder for a brief look at some cooling technologies you have never seen before. We touch on some fun tests from the unpublished Frostytech archives and collect all the thermodynamics research we've reported on into one location.

|

Home >

Reviews >

Page: Annex C) Heat Exchangers, Microchannel, Capilliary, Spray Watercooling

|

IBM Develop High Thermal Conductivity Interface

Technology:

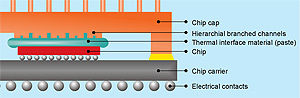

The IBM

Zurich Research Laboratory has developed a technique, called "high

thermal conductivity interface technology," which allows a twofold

improvement in heat removal over current methods. This paves the way for

continued development of creative electronic products through the use of

more powerful chips without complex and costly systems simply to cool

them.

The approach used by IBM addresses the connection point between the hot

chip and the various cooling components used today to draw the heat away,

including heat sinks. Special particle-filled viscous pastes are typically

applied to this interface to guarantee that chips can expand and contract

owing to the thermal cycling. This paste is kept as thin as possible in

order to transport heat from chip to the cooling components efficiently.

Using sophisticated micro-technology, the IBM

researchers developed a chip cap with a network of tree-like branched

channels on its surface. The pattern is designed such that when pressure

is applied, the paste spreads much more evenly and the pressure remains

uniform across the chip. This allows the right uniformity to be obtained

with nearly two times less pressure, and a ten times better heat transport

through the interface.

Looking beyond the limits of air-cooling systems, Zurich researchers

are taking their concept of branched channel design even further and are

developing a novel and promising approach for water-cooling. Called direct

jet impingement, it squirts water onto the back of the chip and pulls it

off again in a perfectly closed system using an array of up to 50,000 tiny

nozzles and a complicated tree-like branched return architecture. By

developing a perfectly closed system, there is also no fear of coolant

getting into the electronics on the chips. The team

has demonstrated cooling power densities of up to 370 Watts per square

centimeter with water as coolant." |

High Heat Flux Nuclear

Waterblocks:

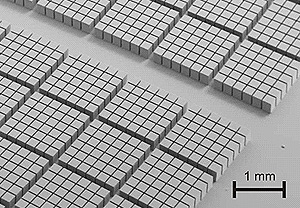

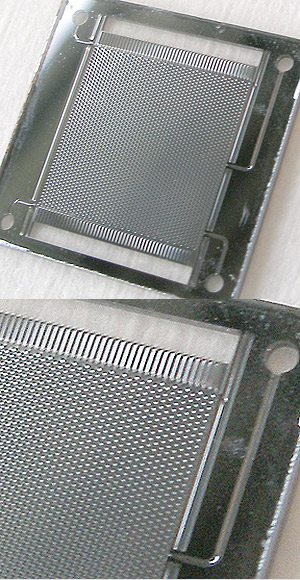

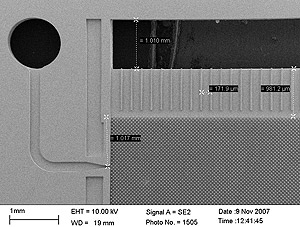

These are three high heat flux (10-20 MW/m2) copper

waterblock test patterns for the International Thermonuclear Experimental

Reactor. Boeing apparently produced these channels with the goal

of incorporating complex coolant channels by close tolerance machining to

create thin webs or slots. These webs and slots are 1-1.5 mm wide and 4-6

mm tall or deep. Although some of the detail parameters are proprietary,

the general design of the coolant channel shows potential for processor

cooling applications. |

|

Thin Film Heat Exchanger :

"The dimensions of MCFs are ideally suited for heat

transfer applications. Due to the small size of the capillaries, the main

resistance to heat transfer is not from the plastic that the film is made

from, but the heat transfer properties of the laminar flow within the

capillaries. This means that, in spite of their plastic construction, the

performance of MCF micro heat exchangers is comparable to those made of

copper where the thermal conductivity of the base material is over 2000

times greater.

The flexible nature of MCFs combined with their excellent heat transfer

properties have led to proof of concept experiments with CPU cooling and

also the evaluation of MCFs in the construction of sports therapy

devices."

CHENG:

"The image above shows the prototype CPU cooler attached to an old AMD

166MHz CPU. With water at room temperature flowing through the film at a

rate of 40ml/min, the chip was held several degrees cooler than with the

conventional heatsink and fan arrangement. With neither the fan nor the

MCF cooler, the CPU would overheat within two minutes."

|

| IBM Cools 3-D Processors with H2O:

"IBM scientists unveiled a powerful and efficient

technique to cool 3-D chip stacks with water. In collaboration with the

Fraunhofer Institute in Berlin, they demonstrated a prototype that

integrates the cooling system into a 3-D chip by piping water directly

between each layer in the stack.

|

|

|

|

1:

Cryo Tech and New Cooling Technologies You Have Never Seen

2:

Thermoacoustic Cooling

3:

Phase Change Waterchilling

4:

Conduction PCB Cooling via Cold Plate Heat Exchangers

5:

The Stirling Cycle Cryo Cooler

6:

Annex. A) Graphite, Carbon Foam/Fiber, Polymer Heatsinks

7:

Annex A) Graphite, Carbon Foam/Fiber, Polymer Heatsinks

8:

Annex B) Diamond, Nano-structure and Metal Foam Heatsinks

9:

Annex B) Diamond, Nano-structure and Metal Foam Heatsinks

10:

Annex C) Heat Exchangers, Microchannel, Capilliary, Spray Watercooling

11:

Annex C) Heat Exchangers, Microchannel, Capilliary, Spray Watercooling

12: — Annex C) Heat Exchangers, Microchannel, Capilliary, Spray Watercooling

13:

Annex D) Computational Fluid Dynamics and Innovative Heatsink Tech

List all FrostyTech heat sinks that Frostytech tested?

|

|

|

|

|

Websites you may also like:

PCSTATS

|

|

|